I recently replaced the front wheel bearings on the bus, not that they particularly needed doing (there was a little bit of play but nothing too serious), more because I was already tearing into the front end to sort out worn wishbone bushes, a seized brake caliper slider and a couple of other bits & pieces – so it seemed like a good time to do some preventative maintenance!

Note – my bus is a 1999 model, so has two separate tapered roller bearings in each front hub with a spacer ring in between them. Models from about 2001 have the bearings in a single cartridge assembly but the process is very similar. (the main difference as far as I’m aware is the bearing cartridge is secured into those hub carriers with a large circlip that needs removing before pressing out the hub)

This job can be done with hand tools but life is a lot easier with a few more specialised bits and pieces, as you will see below. I’ve included some links to my favorite tools used during this job at the end of the article, in case you need to pick up some gear.

Here’s how I went about it:-

Remove road wheel, brake caliper, brake disc and hub cap. As you can see here the brake caliper has been tied up to the suspension spring to keep it out of the way. It is important not to let the brake caliper hang off the hydraulic hoses as this can damage them, potentially leading to loss of fluid and brake failure.

Remove the hub nut. This is REALLY tight! If you’ve though ahead you can loosen this while the brakes are still attached by getting someone to press the brake pedal to stop the driveshaft from rotating while you loosen it, but I’d already removed the brakes so braked the hub with a breaker bar and a couple of wheel bolts to hold it. (In reality the nut can be so tight that the brakes alone can’t hold it, especially without the engine running (so there is no servo assistance)).

You will then need a big bar to undo the nut – I used my comedy oversized ratchet:-

Next step is to remove the hub carrier by undoing the four bolts that hold the hub carrier onto the suspension strut, and another four that hold the lower ball joint onto the hub carrier.

The hub carrier can then be removed from the vehicle and taken into the empire of dirt for the surgery to begin. The drive shaft can slide out of the middle of the hub now the hub nut is removed.

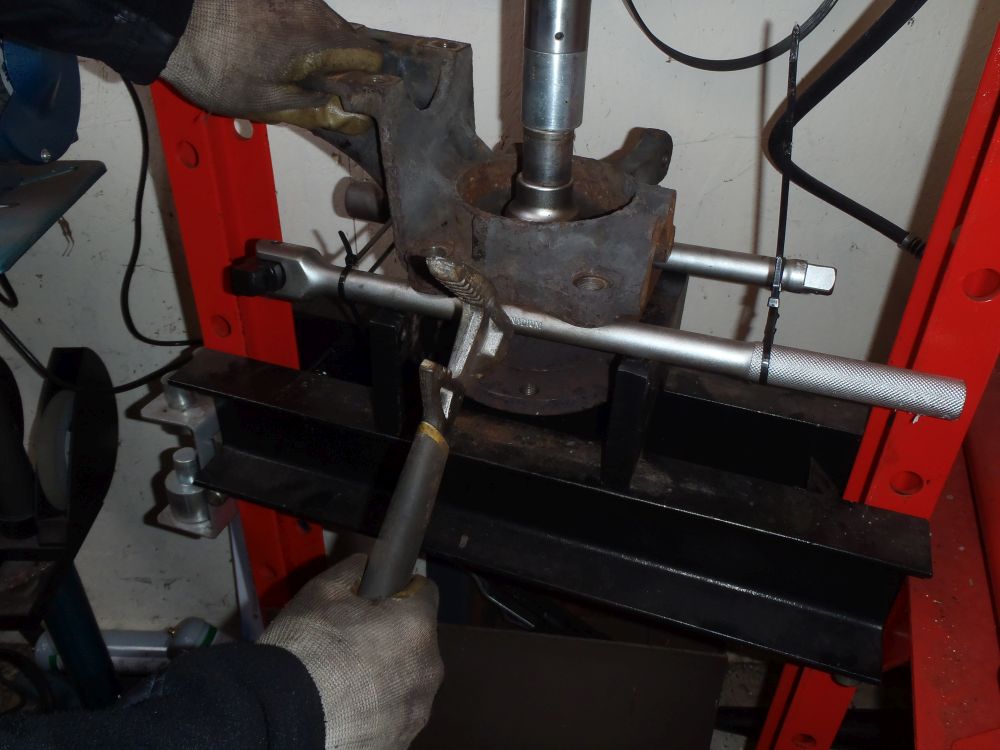

Next step is to press or drive the hub out from the bearings. This means pushing it out from the back of the hub carrier. I used my 12-ton press for this, and I don’t recommend you follow my sketchy example for holding the hub carrier in the press – take your time and devise a better method to hold it, if something gives was while you’ve got a few tons of force on the arrangement things can go very badly very quickly!

While doing this job one side came out fairly easily, but the other was stuck fast – even with a few tonnes on the press it took a bit of ‘percussive persuasion’ to get it to release!

If you get to this point in the job and you can’t get the hub to release the whole assembly is pretty portable, so you can always take it down to your local garage or engineering shop and get them to remove the old bearings and insert the new ones. It should be fairly cheap as it will be a relatively quick job for them, so you still save the expense of paying a garage for the time to strip down and reassemble the front end.

Once the hub had released and exploded bits everywhere we were left with this:-

As you can see the outer bearing and grease seal remained on the hub, so we now need to remove these. I find the easiest way to do this is to lever at the bearing cage until all the roller bearings fall out, at which point you can easily remove the cage and grease seal. With these out of the way the inner bearing race will still be stuck to hub however, I removed this by using a slide hammer with a puller attachment so you can stand on the hub flange and drive the bearing race towards you:-

Next step is to drift the outer bearing races from the hub carrier, one from either side:-

With the old races removed the inner surfaces of the hub carrier can be cleaned up and the outer races from the new bearings carefully drifted into place:-

The bearings themselves can then be packed with grease ready for fitting. I used Molybdenum Disulphide grease and a cheap bearing packer with a grease gun. If you don’t have a packer you can do this by hand, it’s just a bit messier (it’s a fairly messy job anyway!)

With one bearing prepared you can now drop it into the outer bearing race and fit the new grease seal, before pressing the hub back in:-

The hub carrier assembly is then turned over and the inner bearing pressed onto the hub from the other side (don’t forget to put the spacer ring back in before fitting the second bearing):-

Before fitting the other grease seal:-

All complete ready to go back on the bus:-

In the words of a Haynes Manual, ‘reassembly is the reverse of removal’

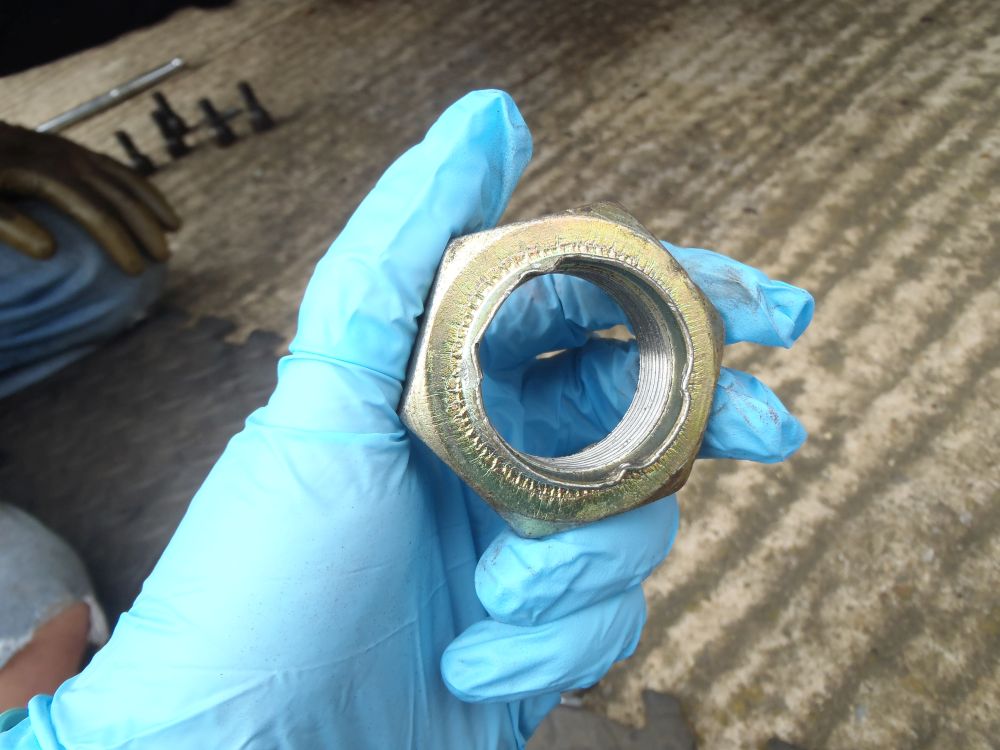

Once everything is back together it’s time to fit the hub nut, torque it to spec (REALLY tight! – 495Nm for the 1800kg payload bus) and stake the nut to secure it. It is good practice to use a new hub nut as it’s a safety critical fastener, normally a bearing kit will come with a new nut but not always (I bought 2x bearing kits from the same supplier, one had a new nut and the other didn’t so someone had obviously been into the box and nicked the nut out of one of them!). If your bearings don’t come with new nuts they can be bought for a couple of quid each.

On our bus the bearings had obviously been replaced previously without fitting new nuts, judging by the two lots of stake marks on the old ones:-

All back together! (you can also see the new brake disc & brake caliper mount in this picture, see the ‘Front Suspension Overhaul’ post for details on this)

Any questions/comments? – let me know below!

Awesome tools for jobs like these!:-

Giant 3/4″ drive socket set, great for large stubborn fasteners and generally breaking stuff. The various sizes of sockets also come in really handy as dies for the hydraulic press!

12 tonne hydraulic floor press – if you’ve ever spent a painfully week end fighting with suspension bushes using heat, hammers, hacksaw blades and vices you need a hydraulic press in your life!. They’re not cheap but worth every penny! These are available in various sizes, both bench mounted and floor standing – get the biggest on you can afford, you won’t regret it……..

Slide hammer, awesome for more stuff than you would think. If you’ve ever needed to hammer on something but not been able to get round the back of it to hammer where you need to, this is the tool for that!

And finally a cheap one, a bearing packer. Not vital but makes greasing bearings a lot easier and can get grease into areas that are difficult to get grease into by hand, potentially avoiding premature bearing failure (which is soul destroying if you’ve spent a whole weekend replacing them!)

October 6, 2019 at 11:55 am

Hi

Great write just tackled same job on my peugeot both side one done lost the spacer

Have you got spacer dimensions by any chance not ripping the completed side out

Thank you

Regards jim

October 6, 2019 at 5:36 pm

Hi Jim – unfortunately I don’t have the spacer dimensions, it might be a question for a Fiat/Peugeot/Citroen commercial dealer parts counter. Also, I believe there are slightly different size spacers fitted during manufacture to account for slight differences in the casting/machining of the hubs, but I don’t know how significant the difference is. Hope you find a workable solution! Cheers, Dan

February 20, 2020 at 3:27 pm

Just noticed this.

I too have lost the spacer, any luck finding replacements?

Seems peugeot no longer supply. maybe Fiat or Citreon do but i wouldnt know parts numbers.

James

February 21, 2020 at 8:48 am

Hi James – I personally didn’t lose the spacers, but I can see how this would be an issue! Fiat or Citroen may be able to help if you speak to a parts counter representative in a dealership, they usually have exploded diagrams where there can look up part numbers.

What may be a problem though is I think there are different size spacers to account for manufacturing tolerances in the hubs – so each spacer is matched to the hub. It should be fairly easy/cheap however to get a general engineering shop to machine a spacer from steel – they’re just steel tubes with an inside diameter the size of the inner bearing race.

If you still have the spacer from the other side they will be able to measure the size of the spacer compared to the distance between the bearing seats in the other hub and work out what size spacer you need for the other size – it will just mean taking both hubs off the van and taking them with you to the engineering shop.

Hope this helps! – let us know how you get on. Cheers, Dan

March 9, 2020 at 9:48 pm

Hi Dan,

sorry for the delay in getting back to you. the weather has been bad and the notion to get this sorted has been difficult to muster. (feeble excuse I know!!).

It wasn’t me who lost the spacer but a local garage who replaced the bearing for me and botched the job up amongst other repairs they were supposed to carry out.

Anyway, I put the vehicle in to a reputable garage who replaced the bearings without the spacer ( at least they told me the issue) and I did about a hundred miles with this setup but after a short time the wheel was getting quite warm if not a bit hot. I jacked up the car and the wheel was stiff to turn so this would be causing the heat issue. I know from reading that the nut has to be torqued up very tight so thinking that this may be causing the bearings to be slightly out of line, I slackened the nut back ever so slightly so that there was no drag when turning the wheel but also no play either. I have done more than 200 miles now and everything seems fine with no drag on the wheel, no heat build up at all and no play in the bearings. As the bearings are very tight on the hub I am thinking that they should not move and also as this is on a motorhome which will only do about 2 to 3000 mile a year I feel that I should not have any more problems.

Thanks for your help.

James

March 10, 2020 at 11:43 am

Hi James – the bearings are taper roller bearings so in theory your approach should work, but there will be a reason the system was designed with the spacer so I would recommend getting it assessed by a professional as a failed wheel bearing can cause a loss of the entire wheel!

The biggest issue I can see is that the wheel nut mostly relies on being tight to not come loose (there is only the small stake holding it in place, if this fails then the nut can come loose and the whole hub/wheel assembly could come off the van). A solution could be to have the stub axle drilled for a split pin and use a castellated nut (assuming one of a suitable spec/thread can be found)

Thanks for the update, good luck with the van 🙂 Cheers, Dan

March 10, 2020 at 11:58 am

Hi Dan. Yes my intention was to keep my eye on the nut tightness anyway.

It is held in place witha collar that you bend a bit of the metal into the shaft groove.

With luck if the bearing was going to fail I would get a bit of warning.

James

November 2, 2020 at 8:39 pm

Just reading this as I have one to do on my brother in laws express 2.5 D motorhome, I cannot understand why the nut is so tight! tapered wheel bearings are preloaded but not significantly so, most use a castle nut with a split pin tightening it so much would surely cause the races to bind? I could understand if a non tapered bearing were used as in a typical back axle. but taper bearings are designed to be adjusted , take up the slack, as they wear, the Hub can hardly fall off, the disk alone would surely prevent that………am I missing something (other than a brain lol)

November 3, 2020 at 8:12 pm

Hi Leonard – the shim in-between the two bearings sets the spacing between the inner races and hence prevents the bearings binding when torqued up this tight (effectively the hub nut clamps the two inner races and the shim to the hub carrier). Why Fiat/SEVEL decided to design it this way – I have no idea! Good luck with the bearing job! Cheers, Dan

November 4, 2020 at 9:46 am

Hi Dan, thanks for your reply, I have stripped the hub down (my brother in laws vehicle) it seems to have been put together wrongly, as it failed an mot on a damaged driveshaft boot …offside hub end, clearly in order to renew the boot the hub had to be dismantled. It seems the oil seals where put on back to front! anyway new bearing kit ordered, I have a manual PDF and an enlarged view shows the cross section, the splined hub buts upto the machined end of the driveshaft just before the shoulder that runs in the inner oil seal, it has a spacer, but no shims, obviously the inner races have to be a tight fit on the rotating hub in order to work but I cannot see the point of using taper roller bearings if the cannot be adjusted, loading a bearing upto the torque required would mean it would not rotate, the can be demonstrated on any car with conventional tapers, take out the split pin tighten it (nowhere near 375 ft/lb) and the wheel won’t rotate! with this design, the hub will surely contact the shoulder on the drive shaft when torqued up to the full amount, the simple sleeve and any shims would simply collapse under that loading it would seem to me that the preloading is non adjustable and cannot take up any wear, so a pair of simple parallel roller bearings would probably be just as effective as fitted in most back axles of course I’m probably wrong!

November 4, 2020 at 7:54 pm

Hi Leonard – no worries 🙂 The spacer in between the bearings should be loaded in compression when the hub nut is torqued – it is reasonably meaty so won’t collapse under this loading and it prevents the compressive force being applied to the rolling elements of the bearings. I believe the main reason for using taper roller bearings is they can handle higher axial loads than ball bearings – if tapered roller bearings are not used some other design (such as deep groove ball bearings) are usually used to handle the axial loads (simple ball bearings are not good with axial loads). I’ve going off memory more then anything and it’s been a while since I did this job! (and my memory is not great at the best of times!) Perhaps you could post a diagram of the cross section? Cheers, Dan

November 3, 2020 at 9:18 pm

Hi Leonard,

just my experience of what i commented on earlier.

In hindsight it may be that the garage didn’t loose the spacer and that it hadn’t been refitted at a previous change but that is a different story.

if you are changing the bearing i would recommend fitting the more expensive option available as the last one i had fitted is still working perfect even though there is no spacer fitted..

As i said i have slackened the nut so there is very little or no drag on the wheel and no play either.

however this is my experience only, so far, and not a recommendation.

regards

James

November 4, 2020 at 9:48 am

that would seem right to me!

March 11, 2024 at 9:42 pm

Hi Dan, not sure if the post is still open for comments or questions. Firstly what a fantastic article. I wouldn’t even attempt this without this article. I have ordered my bearing kits from Coastal motorhomes today. The only thing I am struggling with is the refitting torques for putting it back together. After searching all I can find are french instructions and it’s been a while since I did french at school. My motorhome if a x230 ducato 2000. Any chance you could point me in the right direction for these. No worries if not,

March 12, 2024 at 2:12 pm

Hi Matt – thanks for the comment 🙂 I have a list of Torque specs for the Ducato 230 here:- https://motor-roam.co.uk/fiat-ducato-230-torque-settings. Failing that if you need any help with the French instructions give me a shout – I actually live in France now!. Good luck with the job, cheers, Dan

August 8, 2024 at 10:42 am

Very useful article thank you

My motorhome is 2002 but still has this bearing setup. The left side had play in the bearing so decided to change it and the right side had a split inner driveshaft boot.

I decided to change the shafts and bearings on both sides. I intended to change the hubs (cheap enough on autodoc)and as changing the shafts I angle grinded the hub nuts off rather than struggling to undo them. I hammered out the hubs which eventually just fell out with the inner races attached. I drifted out the inner outer race and pressed out the outer outer race(hope it makes sense). All in all a pretty straightforward job with the help of your photos. I have a silverline bearing removal and fitting kit worth every penny.