During a recent trip to the Alps the heating system in the van failed overnight when it was -15degC outside – we woke to find it was 1degC in the van, cold air being blown from the heating vents and the fresh water had frozen!

Below are some details about how the Truma blown air heating system works, and how to perform some basic diagnostics. This might get you out of trouble but remember that messing about with gas appliances is inherently dangerous, get something wrong and you may gas yourself, blow your van up, or worse! – only work on your system if you are confident and competent to do so…..

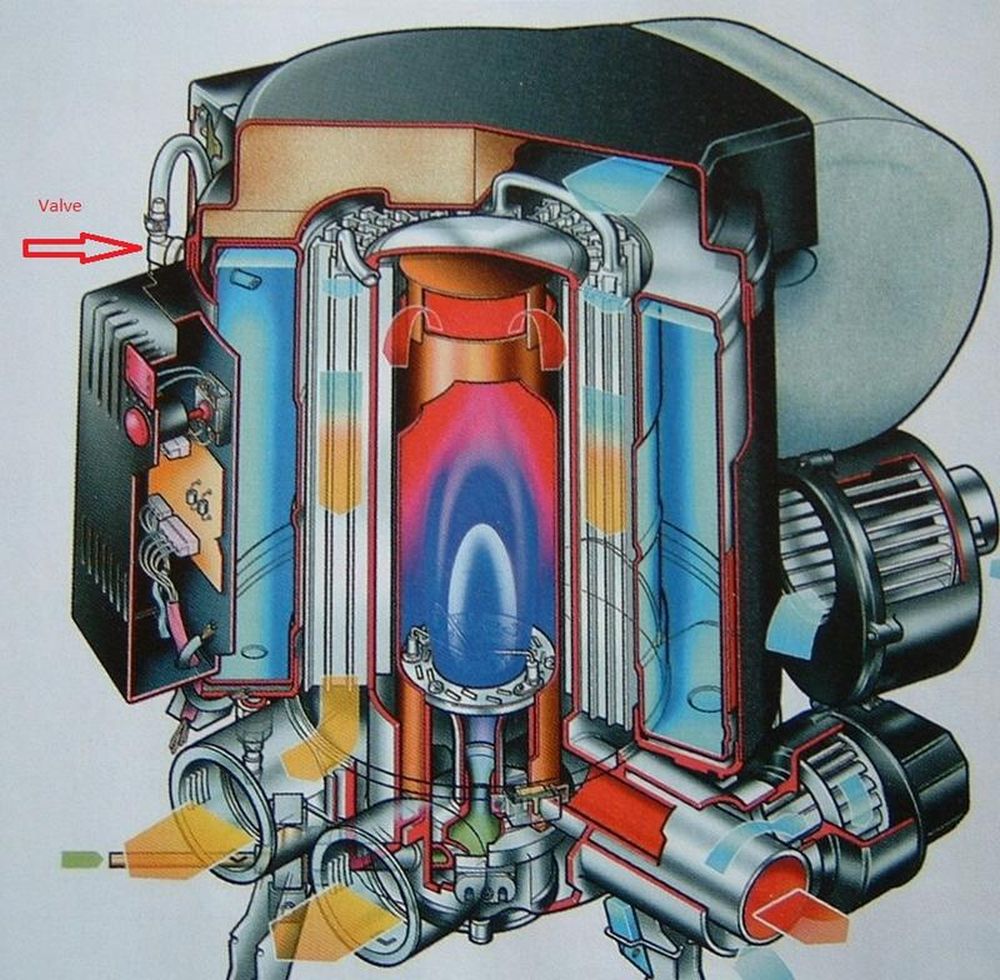

First up – an overview of how the system works:-

The Trumatic C3402 is a gas fired combined hot water and blown hot air heating system. (There are different variants, such as the more powerful C6002 and the newer Combi 4/6. All work on the same sort of principle, the main different being the newer systems are horizontal rather than vertical)

The boiler consists of a central gas burner/combustion chamber, combustion air is blown into the burner assembly by a small fan. The hot gasses pass over a set of heat exchanger fins which surround the combustion chamber before exiting via the flue pipe to the outside of the vehicle. The flue is actually coaxial (think a tube within a tube), where fresh combustion air drawn into the heater through the outer tube and exhaust gasses are expelled through the inner tube. This is a simple yet clever system that helps maximise heat energy extracted from the exhaust gas while also not taking combustion air from inside the vehicle (which would cause a draft somewhere as air would have to get in to the van to replace it)

Surrounding the exhaust gas heat exhanger fins are another set of heat exchanger fins, though these are sealed from the customer gasses. For blown air heating air from inside the van is blown over these fins by a larger fan to heat it up before entering a manifold at the bottom of the boiler where it is blown out through the four hot air distribution ducts.

Finally surrounding these heat exchanger fins is a 12 litre water jacket, and heat energy from the combustion chamber not extracted by the blown air heating ends up in this jacket, heating the hot water.

There are a couple of different style control panels used with this system, ours is the older style which looks like this:-

There are some switches to select between off/hot water only/hot water and heating & for selecting the hot water temperature, a thermostat knob for setting the room temperature and some lights to let you know what is going on.

Diagnostics

The boiler control panel red light will flash if the battery voltage is too low to operate the unit (about 10.5V I believe), and light up solid red if the boiler has ‘locked out’ (shut itself down due to something being wrong)

In theory a lockout can be caused by a variety of things, such as:-

- No combustion airflow detected

- No flame detected

- Boiler overheat

In our case when we woke in the morning there was no red light on the controller and the combustion and room fans were still running, suggesting the boiler thought everything was fine – the flame had clearly gone out though!. I reset the system (turned it off and on again!), the boiler attempted to start but went to a lockout state (red light) shortly afterwards.

In a normal startup sequence (hot water demand only) you can usually hear the various parts of the heater operate this order:-

- Combustion fan starts (think a quiet-ish fan noise)

- Gas solenoid operates (loud click) and gas ignitor starts firing (fast sequence of quiet clicks, you have to be very close to the boiler to hear this)

- Gas lights (a muffled thump type noise from inside the boiler)

Note: if you have the control panel set to heating and hot water the room fan will run also. The same sequence of events above will still happen but the noise from the room fan makes it harder to hear what is going on!

First things to check are is the gas still working (checking the hob is the easiest) and battery voltage. Our hob was working fine and the battery was reading 11.9V so it all looked OK. Note: Butane gas will not vapourise below about 3degC so Propane is required for cold weather use, we were in the mountains in the winter so had two 11kg Propane cylinders on board.

Our system seemed to have developed multiple faults all at once, sometime the gas would light but the ignitor would then start firing again (even though the boiler was still lit) suggesting the boiler thought the flame had gone out. Occasionally it sounded like the gas solenoid hadn’t fired at all (suggesting either a defective solenoid or defective driver circuitry). Sometimes the system would run but then the room thermostat became unresponsive (the system would shut off when the van got up to temperature but then not re-start when it cooled down).

To me this pointed to a defective PCB (main control board) – as this was the only component I could think off that could cause so many of these symptoms. Either way it was time for a strip down and inspection to see what was going on, the unit had been rattling around in our old bus for the last 18 years after all and we’ve got no record of it ever being serviced!

Strip down and inspection

In our Hymer B544 the boiler is located underneath the wardrobe, emptying the wardrobe and lifting up the base allows you to see the unit as installed:-

Here you can see the exhaust/combustion air flue (black hose), hot air ducts (brown hoses), PCB (control board) housing (black box on front of boiler) and hot water outlet (red hose connected to right hand side of unit)

You can also see the 240V inlet (white unit in side of van behind boiler) and 240V distribution box (white box in bottom right hand corner of picture) – but these don’t have anything to do with the Truma system!

The small black box with the red knob on it (between the two left hand hot air ducts) is the frost protection valve. This is connected to the water system and opens if the temperature in the van drops below about 4degC, emptying the contents of the boiler out underneath the van. This is to prevent the boiler freezing with water in it causing the hot water cylinder to crack. This vale is held closed electrically so if you disconnect the habitation batteries or blow the fuse supplying 12V to the heater it will open and drain the boiler. Once it has activated it has to be manually reset by pulling the red knob upwards (if you need to keep it closed temporarily but the temperature in the van is too low to allow it to latch a clothes peg can be used to hold it closed, don’t forget to take it off once the van has warmed up though!).

Here is another view of the frost protection valve:-

Removing the shelves in the lower section of the wardrobe and unscrewing the wooden panel behind them allows much better access to the unit:-

You can now also see the electric ignitor unit (small blue box clipped to the right hand mounting leg under the boiler)

Removing two small screws in the top of the PCB housing box allows the cover to be removed for access to the PCB:-

I’ve unplugged the electrical connections in the above photo, the board is just clipped into the housing so can easily be removed for inspection now. There was no obvious problems on visual inspection (no burnt looking components, leaking capacitors or damaged solder joints, but I lack the electronic diagnostics skills to go much further than this!)

The room fan and housing unit can be removed by disconnecting the electrical connection to the fan (down the back of the unit near the fan) and undoing the 4x 9mm plastic nuts on the top of the unit. The whole assembly can them be lifted up and removed, leaving the boiler looking something like this:-

Here you can see the central can housing the burner/combustion chamber, the outer heat exchanger fins that the room fan blows air over and the hot water cylinder on the outside.

With the fan housing removed you can get down the back of the unit to disconnect the flue – warning: it can be difficult to get it reattached and you are supposed to use a new o-ring on the exhaust connection whenever the flue is re-attached so I don’t recommend disconnecting it unless you have to. I disconnected it to check for excessive soot etc. in the exhaust which would point to a combustion problem, but it was all clean in my case.

To get access to the burner assembly you now need to move the whole unit. First job is to disconnect the hot air ducts – unfortunately they are held in place with little plastic tabs top and bottom that have to be depressed to withdraw the duct, and the top tabs are almost impossible to access with the unit assembled (it doesn’t appear to have been designed for disassembly!). I opted to just remove the front two duct hoses (which involved breaking the top tabs on each one) and leaving the rear ducts connected. It meant I couldn’t remove the whole unit from the van but I could at least turn it on its side to work on it.

Here is a view of one of the disconnected hot air ducts, you can see the locating tab on the white collar on the end:-

You also need to disconnect the gas supply to the unit. In the above photo I have already disconnected it but you can see the union on the boiler where it attaches (in front of the red hose underneath the boiler) – don’t forget to turn the gas of before you disconnect it! (in fact – don’t forget to turn the gas off before you do any work on the system!)

The unit is bolted down on three legs, with these undone, the cold water feed to the unit disconnected (I disconnected it at the frost protection valve) and the electrical feed disconnected (mine was connected on a flying lead near the frost protection valve) the unit can be carefully lifted up and turned over for access to the underside:-

The burner assembly can now be seen held into the bottom of the unit by three 8mm nuts. To remove it you need to take the gas valve/solenoids off (held on by two screws, it has already been removed in the above photo but it would have been attached to the burner behind the water hose at the bottom of the photo). You also need to unscrew the combustion fan air feed ducting (black plastic housing in the middle of the photo) – there are three screws that attach this to the burner, two are obvious but one is hidden inside the ducting to get to it you need to remove the air flow sensor from the ducting (the little pcb you can see next to the ducting in the photo above). With this removed you will be able to see the screw inside the ducting, a feed a long screwdriver down through the mounting leg and into the ducting to remove it (see photo above – I left the screwdriver in to make it clear!).

The three 8mm nuts can now be removed and the whole burner/combustion chamber assembly slid out of the bottom of the unit (it may take a little persuasion as it’s likely been in there for at least ten years)

This is the whole assembly out of the boiler, with the electric ignitor unit still attached:-

The combustion chamber (large metal tube over the burner) can just be slid off. This is what my burner looked like underneath:-

There is a bit of soot buildup in the middle of the unit but generally it looks it decent condition. The probes are looking a bit worse for wear though. (the two close together are connected to the ignitor, it creates a high voltage spark between these electrodes to light the gas. The probe on its own is the flame sensor – the boiler uses this to know if the gas has successfully lit or not, or to tell if the flame has gone out during operation)

I believe you can buy new electrodes separately and they should be easy to fit once you have it all apart like this, but I found a good deal on a whole burner assembly so I decided to replace the whole thing.

Note – it looks like the boiler uses ‘flame rectification’ to detect if a flame is present, and the electrodes in these systems are very sensitive to dirt/corrosion on the electrode. It is entirely possible that just cleaning up the electrode with fine wire wool would have fixed the problem, but after getting this far into the guts of the unit I didn’t fancy trying it in case it didn’t fix it and I had to pull the whole lot apart again……..

Here is the shiny new unit:-

I also decided to replace the PCB as I found one for a good price. It’s actually from a later version of the C3402 and not completely identical, but looked close enough that I was willing to risk it! (all connectors are the same and most of the circuitry is identical, some of the components have been moved around a bit and the relays are from a different manufacturer. There is also a few additional components the original board didn’t have, which I think are to support some remote start functionality).

Here is a picture of the new board I found, in case you want to play spot the difference with the original further up this page!:-

With it all back together with the new parts everything seems to be working OK again – we’re back off to the mountains in a few weeks so I’ll update this if any of the faults reappear, or if it develops any new ones!

p.s. before doing any of this I did contact Truma technical service with details of the symptoms, but the best they could suggest was to get it booked in to a motorhome dealer for a full strip down and inspection. As you can see the strip down is reasonably labour intensive so while I didn’t bother to get a quote from anyone it’s fair to say it would have been expensive – especially when you are as tight as I am! – I opted to save the money and treat it to some new parts instead…

Hopefully this information has been useful – if you have any questions or comments please leave them below…….

UPDATE! – A reader has been in touch to share his experiences of a ‘blow back’ in the exhaust flue and the root cause of the problem, Many thanks to Marcus Tompkins for this information:-

“I had a “Blow Back” with my Trumatic C 3402 which blew the end off the external plastic cowl… I found the broken pieces and glued it back together for a temporary fix. … Boiler would not stay alight afterwards and “lock out” red led would come on….. it would light but only for 10 seconds max then shut down…. I replaced the flame detection electrode but still no fix…. turned out to be the flue pipe had sheared off where it connects via a clamp to the external cowl…… this caused the gas and air mix to be wrong therefore putting system into Lock down.

Hope this may help any other “have a go” repairers.”

UPDATE #2! – A reader is having some problems with a Truma roof cowl, if you have any experience with the roof mounted vents/cowls please take a look here and see if you can help!

UPDATE #3 – No hot water from your boiler? – click here to read how a Motor-Roam visitor diagnosed and fixed the problem……..

UPDATE #4 – Another reader (Paddy – see comments) was having problems with inconsistent starting of his boiler. When he stripped it down to investigate he found the ceramic holder of one of the electrodes had broken, allowing the electrode to move around inside the boiler. With this replaced his system is now working perfectly again. He has pointed out that the screws holding the electrodes tend to rust into the burner, so a good soak with penetrating oil beforehand is recommended! – thanks Paddy!

Here’s a picture of Paddy’s broken electrode:-

Found this information useful? – Want to support Motor-Roam?

Click here to find out how!

February 28, 2018 at 8:09 pm

Brilliant thank you

March 1, 2018 at 6:25 pm

No problem Barrie! Thanks for the feedback!

October 17, 2024 at 9:53 pm

Hi Dan

I was send my this great article from a fellow Truma C user when I posted about my issue with the boiler blower fan going continuously even with the controller set to off The only way to stop is disconnecting power completely (pulling the fuse out) but as soon as the fuse is back in the blower kicks into action again

Thus fault happened after the room heater running for about 2 hours and then switched off. The fan hasn’t stopped since !

Now when I select any mode of heat the boiler goes into fault mode a few seconds after the main solenoid activates.

Does this ring any bells ? Any advice would be greatly appreciated

October 20, 2024 at 6:54 pm

Hi Declan – is it the room fan or the combustion fan that is running continuously? My suspicion would be a fault with the PCB – the easiest way to test this would be to swap it out for a known good one, if you know anyone with the same model heater they may let you borrow their PCB for a test…..

Regarding the boiler going into fault, is it igniting once the gas solenoid activates then going into fault, or is it not igniting? Cheers, Dan

October 22, 2024 at 9:04 pm

Hi Dan

Apologies for the late reply. I missed your post somehow. So I think it’s the room fan that is constantly on as it’s the very loud one.

I removed the PCB and found burn marks on the underside of the component with the big metal heat sink at the bottom right side of the board.

I sent the board away yesterday to a guy I found on eBay who offers a test and repair service for Truma combi PCBS. Hopefully he can repair it and thus will fix the issue.

However I’d like to know what caused this component (a MOSFET I believe ) to burn out on the first place as it may end up blowing again!

Also as an aside I noticed there is a flying lead with two wires terminated in a double spade connector coming out from the main PCB lower harness that is not connected to anything. Not sure if this is for some optional feature but I can’t see anywhere it can plug into. Any ideas?

Declan

October 23, 2024 at 8:10 pm

Hi Declan – hopefully your PCB expert can shed some light on the problem! The harness you mention might be for a frost protection valve? – does your system currently have a frost protection valve plumbed in? Cheers, Dan

September 21, 2018 at 2:33 pm

My Sister has this system on Laika Ecovip. On doing some work on the roof, I noticed that a cowl had been fitted to the external pip that was not giving cover for water ingress. It looked like the common Trumu chinese hat model that is on my old caravan. I ordered up the “proper”? cowl from Leisuredirect. It has the straight sides and the arrow for pointing to FRONT. I think there is still something missing though, like a spacer collar. Perhaps this one blew off too and bits got lost? Even this new cowl looks to have a smaller dia than the service pipe on the roof? How can it shed water over the pipe, when it has no overhang?

September 21, 2018 at 6:01 pm

Hi Alex – I’m afraid I don’t have any experience with the roof mounted cowls but I found these instructions for a roof cowl extension on Truma’s website:- https://www.truma.com/web/downloadcenter/files/truma-heating-cowl-extension-kvc-combi-installation-de-en-fr.pdf – There is a exploded diagram of the cowl so you may be able to compare and see if you are missing any parts. Alternatively someone else reading this might be able to help? Feel free to e-mail a photo to technical at motor-roam.co.uk and I can post it up on here to see if anyone can help. Cheers, Dan

September 21, 2018 at 11:02 pm

Thanks a lot Dan. I will get a few pics up. I have searched google images for weeks, and I cannot find an image of the real life cowl on the roof. I have studied the drawings, which led me to buy the cowl that is shown.

Regards

Alex

September 25, 2018 at 8:28 pm

Hi Alex – I got your e-mail but the reply bounced back? Anyway – I think the gap around the larger tube is the air inlet and the hole you mentioned is for a screw, possibly to fix an outer case that has gone missing? That said I’ve not seen that type of cowl before so I’m guessing! I’ll post the pic up on here and see if anyone else can shed any light on it!

Cheers, Dan

September 30, 2018 at 10:08 am

Thanks a lot Dan.

I am guessing that the largest pipe should be watertight, but not air tight. The cowl provides an outlet for gas fumes only, through the inner stainless flue. The other tube that contains that exhaust duct, must draw air through the actual exterior pipe chamber, not the roof cowl itself. If anyone has a pic of a set up with the plastic cowl on the roof, which is semi square, that would be great!

March 1, 2018 at 1:25 pm

Fantastic. Hope I don’t need it, but thank you.

March 1, 2018 at 6:24 pm

Thanks for the positive feedback David!

March 3, 2018 at 11:09 pm

Mine is doing about the same and left us pretty cold in minus7 last week. The above was very good thankyou but as my unit is only three years old, (fitted to a Hymer Carado) I doubt much could have Ron out yet. True to say I haven’t had a chance to look at it since getting back home due to the snow etc but will be as soon as the weather improves… Thanks again…. Regards… Pete Osborne

March 4, 2018 at 11:04 am

Hi Pete,

Thanks for the feedback – hope you get your unit sorted! Let us know how you get on with the investigation…………

Cheers, Dan

May 26, 2018 at 1:34 am

Very interested in your article. Am down here in nz with identical 3402 that needs rebuilding. Whatsource of parts did you use

May 26, 2018 at 9:53 am

Hi John, the burner assembly came from Leisureshopdirect.com – they stock lots of parts. The PCB was a bit harder to find (for a sensible price at least) – I ended up finding a new old-stock PCB on eBay being sold by Yorkshire Coast Caravans (www.yorkshirecoastcaravans.co.uk/)

Hope this helps! Cheers, Dan

June 1, 2018 at 7:58 pm

Hi Dan, thanks for the very good write up. i have the same boiler in my Hymer and i’m plucking the courage up to tackle it. But the hardest thing for me is the fault diagnosis. I like you don’t have a massive stock room of parts and buying parts to replace what might be wrong would be expensive. So heres the million dollar question. My boiler goes through all the usual start up procedure, 1 combustion fan running 2 gas solenoid clunk 3 ignitor clicking away 4 the muffled whump of the gas igniting BUT it does this the muffled whump three times and then the red lock out light comes on. So the gas is refusing to stay lit. Could this be the flame rectification electrode? I hope i’m right and that you can verify this for me then i can buy the offending part and replace it.

Regards

June 1, 2018 at 8:35 pm

Hi Graham – I’m an engineer by trade but full disclosure – I’m not a gas boiler engineer! It sounds very much like controller is not detecting the flame which is more than likely the flame sense electrode, but could always be a problem with the PCB (controller not reading the signal from the flame sense electrode properly). The electrodes are available separately and quite cheap, but it’s a reasonable amount of work to strip the boiler to get to them. One the plus side if a new electrode doesn’t fix the problem the PCB can be changed in about five minutes without dismantling the boiler again, but it’s a much more expensive part!. Hope this helps………cheers, Dan

June 2, 2018 at 4:34 pm

Great article: thank you. My heater unit has simply gone dead from the control/thermostat end, with no lights showing whatsoever.

Have obviously checked the basics, including voltage testing each connections into the control panel… but no readings whatsoever.

Strange because it worked fine last year. Can anyone shed any light on this problem, please? Thanks in advance ~ Eddy

June 5, 2018 at 11:35 am

Hi Eddy – I’m afraid I can’t find any wiring diagrams/schematics for the control panel but I can’t imagine it is very complicated. Have you checked performed a continuity check from the panel to the connection at the PCB to confirm all the wiring is intact? Is there power to the boiler? (no power to the boiler would mean no power to the control panel)

If both of these are OK then it could be either the control panel (relatively cheap) or main boiler PCB (expensive) that is at fault – do you know anyone locally that have the same boiler/control panel? – they may let you swap parts out for known good ones as a quick check to confirm which part is at fault before you order anything. Hope this helps!, Cheers, Dan

June 10, 2018 at 9:23 pm

HI, Very informative, thank you,

I have recently purchased a 1998 Hymer Starline in need of of some all round TLC.

I have decided tackle the operation of the boiler first. Maybe someone could give a newbie a steer in the right direction!

Up on filling the boiler with the taps open the air will purge through and the water will start to come out, however it will also start to come out of what i believe to be the hot water connection and vent valve? (It looks like it the valve labelled in red on the above cross section diagram.) Any help or advice greatly appreciated.

June 11, 2018 at 8:49 am

Hi Gordon – the vent valve on the photos above has a clear hose coming out of the top, with a red hose coming off the underside. The red hose is the main hot water outlet from the boiler, so when you are filling the boiler the water will flow through the red hose once the air is purged. If it is flowing out of the clear hose it suggests the vent valve has failed (this is an over-pressure vent, from memory).

If water is coming out of the frost protection valve (will usually drain out underneath the van) then the red knob needs pulling back up to shut the valve – note it is held closed electrically so if there is a supply problem to the valve the knob will not stay in the ‘up’ position.

Hope this helps! Cheers, Dan

July 21, 2018 at 7:30 pm

Good article my truma wont go to stage 3 of the combustion process.Water heater side works but not blown air side.Tested by Truma who say it has a fault on pcb but no other info very helpfull.Cant seem to locate a pcb was interested to hear you put differant one in yours did this work ok?.If it did can you give me a number for it any info would be good

July 22, 2018 at 5:12 pm

Hi Bob,

Thanks for the comments – It’s a good sign that the water heating side is working OK as this means all the gas control/safety stuff is working OK. If it’s not running the room fan it could be an issue with the thermostat or the fan control speed control stuff on the PCB. In an emergency you could probably power the fan directly as this will take heat out of the system and when the water drops below the set temperature the boiler should fire itself back up to heat the water – not as well controlled as when it is working properly but at least you would get hot water and some room heating!. The replacement PCB is working fine in my unit despite being slightly different than the one that came out of it. The part number was 34000-77000 and it came from Yorkshire Coast Caravans but I think it was old stock they found lying around rather than a part they normally carry in stock. Truma have an online service portal at https://www.truma.com/uk/en/service/service.html and they are quite helpful so should be able to help you source a new part – it is likely to be quite expensive though!

Hope you get it sorted, let us know how you get on…..

Cheers, Dan

November 15, 2021 at 9:25 pm

Absolutely brilliant article I have a Eura Mobil 810 Integra and my Truma 6002 has just started having ignition problems. At first it would light if I dropped the thermostat to 5 degrees until lit then increase but a few weeks ago this stopped altogether! I can now also smell electrical burning when I tried to put it through the start process. I have had a visual inspection of the PCB and everything looks okay. I am going to get it tested by a friend when I get back to work but after reading this I am thinking I should strip down the unit and check the electrode condition ? The other problem is there are no spare parts available now in 2021. I have found a 3402 unit for sale for £200 is this compatible with the 6002 if I need parts ?

November 16, 2021 at 7:00 pm

Hi Mark – Thanks for the comment. it’s probably a good idea to check the condition of the electrodes. The C3402 & C6002 share a lot of parts but I don’t know exactly which bit are compatible between the two units. You should be able to use the information here to cross-reference the parts numbers and see what it fitted to both units:- https://www.leisureshopdirect.com/gas/camper-van-conversion/truma-heaters/trumatic-c-6002-c-3402-spare-parts

Hope this helps!, Cheers, Dan

May 25, 2023 at 12:54 pm

Hi Bob.

Just wondering how you got on with your circulation fan fault. I’m having the same issue, heating the water is perfect, the heat only function turns the initial fan on but won’t turn the circulation fan on and just clicks.

The only way to get the circulation fan to run is heat the water to 60c and then turn the heating on. The fan runs for about 2 mins and gets progressively slower until it stops.

July 29, 2018 at 10:52 am

Brilliant!!…..very helpful article Dan.

I had a “Blow Back” with my Trumatic C 3402 which blew the end off the external plastic cowl… I found the broken pieces and glued it back together for a temporary fix. … Boiler would not stay alight afterwards and “lock out” red led would come on….. it would light but only for 10 seconds max then shut down…. I replaced the flame detection electrode but still no fix…. turned out to be the flue pipe had sheared off where it connects via a clamp to the external cowl…… this caused the gas and air mix to be wrong therefore putting system into Lock down.

Hope this may help any other “have a go” repairers. All the best Marcus.

July 29, 2018 at 11:14 am

Hi Marcus – useful info, many thanks! – I’ll add this detail to the main article so it doesn’t get lost in the comments. Cheers, Dan

August 6, 2018 at 7:41 pm

Hi, this is a very informative article about the truma c4002.

my c4002 has stopped working and shows a fault red light as soon as I switch it on.

no fan noise or clicking. gas supply is ok.

Can I ask do you know if the grubscrew on top of the pcb board is needed as there is none on mine.

you can see it on your photos before and after you opened the pcb cover

It might be my problem but I am not sure.

Thanks

August 6, 2018 at 10:29 pm

Hi David, Thanks for the comment! By grubscrew do you mean the component in the centre at the top of the PCB pictures? – this is actually a connector for a remote room thermostat (the connector is like a 3.5mm headphone audio jack). I think the c4002 has a different method for adding a remote thermostat which might explain why yours doesn’t have one. Is your red light solid or flashing? (a flashing red light would indicate low 12V supply to the unit)

If the light immediately goes red the first thing I would look at is the combustion fan (as starting this fan is the first thing the boiler does) – check the simple things first – has it become disconnected?, has it seized up?. If all seems well you could try measuring the voltage to the fan to see if the PCB is sending power to it.

Hope this helps!, let us know how you get on………

Cheers,

Dan

August 19, 2018 at 3:03 pm

Hi Dan, i have a Eura Mobil van 2003 with the Trumatic C 3402, I am in the Midlands, it sounds very much like the problem i have, Sometimes the boiler will fire up for hot water, but when i switch to Heating, it goes through the process where you can hear it trying to fire up, it usually makes a clucking sound 3 to 5 times before the red light goes on. I was in Italy recently and they were asking close to 1000 Euros to fix it but they didn’t actually have the parts, also they wouldn’t give me the information of the problem when i said i couldn’t wait a week for them to ship the parts in. I am guessing but it sounds like my pcb board could be the issue also. when you say it is expensive, how much is a PCB from the dealer?

thank you for your time.

Matthew.

August 19, 2018 at 5:52 pm

Hi Matthew – it’s interesting that it works on hot water but not heating, as the start up sequence is essentially the same for both (the only difference with heating is the the system will run the room fan and sometimes the second gas solenoid for a higher output (the second solenoid will operate if there is a large difference between the room temperature and the thermostat setpoint)). Does it always work on hot water or does it sometimes fail in this mode too?. On startup the sequence should be combustion fan starts and fast ticking sound from the ignitor>louder click of the gas solenoid operating>’whumph’ sound as gas ignites – if the ignitor continues to tick after the gas has lit this indicates the boiler doesn’t think it is lit so it could just be a problem with the flame sense electrodes. If it is the PCB last time I looked they were about £330……

Cheers, Dan

November 14, 2019 at 7:43 am

TRY BOB GARDNER FOR TRUMA PCB HEALTH-CHECK/ REPAIRS, MY PHONE NO. IS 07887705480 DONT STRUGGLE BUT PLEASE HAVE A DETAILED LIST OF WHAT YOUR EXPERIENCING HANDY, I CAN ADVISE BEST COURSE OF ACTION.

HOPE THIS INFO. HELPS

November 4, 2020 at 7:22 am

Hello

Can you write to me your e-mail address. I need some information but i want first to send some details

I am from Hungary

September 26, 2020 at 7:54 pm

Hi Matthew.

Did you get this issue resolved? I have exactly the same problem with my C6002.

It used to be that it would not light at all on gas unless I first warmed the solenoid valve area. This could be done by switching it on using mains or simply stuffing a hot water bottle in there. I assumed a faulty solenoid vale and fitted a new one.

Now, it works perfectly for hot water but for heating, it tries to ignite about 5 times then I get the red fault light on the control unit.

September 13, 2018 at 9:35 am

Hello,

Our gas is working (powers the fridge and we can use the Hobs)

However the boiler doesn’t seem to be able to light? Can we manually ignite or is it a case of taking everything apart?

September 13, 2018 at 10:17 am

Unfortunately the burner assembly is right in the middle of the unit so there’s no real way to manually ignite it – are there any clues as to what is stopping it lighting? (can you tell where in the startup sequence it fails?) Cheers, Dan

October 14, 2018 at 9:31 pm

Hi Dan, Thanks for documenting the strip down of the Truma. I learned a lott. I just bought a 1996 Hymer B544 and found out that it got a problem with heat water not flowing thru it. Its a Trumatic C3400 . You seams to have good knowledge on these heaters. Do you have any tips on hot water debugging or where you can buy spare parts for these old models? I suspect that the frost gard is somehow blocking the water from entering the heater.

Regards Nils

October 15, 2018 at 10:14 am

Hi Nils – glad you found the info useful! Assuming your water pump is working OK if the frost valve is open you will normally see water coming out underneath your van when you try to draw hot water. I would try unscrewing the valve off the boiler hot water output – if you get water coming out of the boiler where the valve was it is likely the valve is blocked. If there is still no flow you could try disconnecting the input hose and blowing through it to see if the boiler itself is blocked – it’s possible it needs descaling but they generally won’t get bad enough to block completely. It could also be that the water pipes are blocked somewhere else in the van – is this is the case you will just have to work your way round disconnecting and blowing through them (with the taps open and the water pump off) to find the blockage.

I get a lot of my spare parts from these guys – https://www.leisureshopdirect.com/

Hope this helps!

Cheers,

Dan

October 15, 2018 at 6:19 pm

It was the actual truma boiler that was blocket. Somewhere between the frost guard and the boiler. That was why I could not get any water through the hot water tap. I disconnected the frost guard and the pipe between the frost guard and the boler I could se a sluggish paste in the pipe and since no water came flowing back i suspected that there were something blocking the inlett to the boiler. I bought a pipe cleaner for kitchen sinks and pulled it back and forth until the water and bits of gray paste started flowing back from the boilers inlett. I connected the pipe back to the valve and drained the boiler from water. Now I have filled the boiler and freshwater tank with a mixture of citric acid and hot water (500gr pr – 50l ). I have flushed it trough the system and are going to leave it in in the boiler overnight. Tomorrow i will use the valve to empty the boiler the bottom so the deposits of scale will hopefully pour out that way and not clog upp something ells. And if more people have the same problem I hope that this description could help them as much as your tear down helped me.

Regards Nils

October 15, 2018 at 6:23 pm

Hi Nils – glad to see you’ve found the problem! Hope it’s all sorted in the morning 🙂

Cheers, Dan

January 5, 2019 at 4:42 pm

I have a Trumatic C3402 – 2002, ex hire. Boiler works ok but i am getting a high pitched alarm from time to time. It will only go off by switching off leisure battery power. Back on again and its ok – for a while. Ok now. Seems there is no theft alarm on van. I have been through a number of sequences and unable to identify cause. Only came into it after lay up over winter. My guess was that it was to do with a gas alarm, when the boiler did not fire up on first go. Can’t find alarm. Any ideas please?

January 6, 2019 at 4:59 pm

Hi Roy – can you pinpoint where the alarm is coming from? – it’s location might give a clue about the cause. It may be a low battery alarm (batteries drained after long lay-up), what state were the batteries in when you had the alarm? Cheers, Dan

January 9, 2019 at 4:43 pm

Hi Dan,

Batteries, both leisure and van are indicating well up, fine. My problem is the noise is so intense, it just seems to be coming from everywhere.

I tried the fridge today, hasn’t been gas on for a long time. It took a little, but very little coaxing, to ignite – alarm went off during the process. It resets to off, immediately you turn of and on battery supply on panel. Leading me to suspect some kind of gas leak alarm.

There is a hidden spot in upper presses I am going to try to disassemble, to see what’s in it.

I will try seperate test on batteries, and have a look behind the Schaudt IT 992 Instrument panel.

Thanks for your help, as you might appreciate, it is something I have to nail down before I bed down beside a neighbour!

January 9, 2019 at 7:48 pm

Hi again Roy – you can normally smell a gas leak (though it may be too slight for you to notice), is there any smell of gas while using any of the appliances? It may me worth getting some leak detector spray that you spray onto any gas unions and look for bubbles, though many of the unions are difficult to access. If it is an option it may be worth getting a habitation service that includes a gas safety check. Hope you get it sorted! Cheers, Dan

January 10, 2019 at 10:26 am

Hi Dan,

Thanks for that. Eliminated behind controls panel – no buzzer.

Eliminated behind boards up in presses – int & ext light relays.

Can’t smell gas – but will test for.

I’ll have to find that buzzer – it makes so much sound you would think it would be obvious. Thanks again.

Roy

January 10, 2019 at 11:24 am

Hi Dan,

At floor level – 1mm off – I found a sensor like the head of large screw – pressed it, and off it went. Located gas alarm and siren tucked away behind the leisure battery. Obviously very sensitive and something is setting it off just after ignition. Happy days, and many thanks.

January 24, 2019 at 1:42 pm

Hi Dan, what a great write up! I’m hoping it’s helped me a little by eliminating the requirement to change the ignition kit. Mine is a C6002 so is quite powerful I believe. I recently had a problem with cluster flies living in the flue system. I had to remove the whole unit and replace the intake and extract flue. I managed this ok but I still have a problem with the heating side of the boiler. Hot water is fine and the usual fan, solenoid etc can be heard and it fires up ok. So now I switch it to heating and hot water. With the thermostat turned right down the boiler fires up ok to heat the hot water and the fan is running, when I turn the thermostat up to bring on the heating I hear the louder fan kick in and run but then the boiler starts to try to ignite. I can hear what I presume is another solenoid (required for the extra boost of gas supply for the heating) but then it closes and tries again. This continues again and again until I switch the thermostat down where it then runs ok again for the hot water. Do you have any ideas what this could be as I really don’t want to buy another PCB because I’m tight like you 🙂

January 24, 2019 at 1:56 pm

Hi John, Thanks for the comment!

The C6002 is a big brother to the C3402, more powerful and has a few extra features I believe, but it works on the same principle. Your symptoms sound interesting, it is normal for the boiler to actuate the second solenoid for extra gas when there is a large room heating demand, this should be the click you hear (which suggests that the solenoid is being actuated OK). If the boiler is repeatedly actuating this is sounds as though it believes it is not working, I’m not sure how it is working this out as at this point the boiler should already be lit (from the first gas solenoid) so the flame sense will already reading as ‘lit’ – adding in the gas from the second solenoid should just make the flame stronger.

It is possible there is a temperature sensor somewhere in your boiler that is not detecting the increase in temp it expects?

My best guess for the root cause is a blocked solenoid/gas jet – so the solenoid is actuating but no additional gas is flowing. You should be able to remove the solenoid assembly from the side of the boiler for inspection without disturbing too much other stuff.

Hope this helps, let us know how you get on! Cheers, Dan

February 21, 2019 at 10:41 am

Thanks for the reply Dan, for some reason I didn’t get a notification of your reply and only just seen it. I replaced the main PCB as I managed to “borrow” one. It didn’t solve the problem. I noticed one of the clamps securing the exhaust duct was not the correct type so I have replaced that. But before I put the whole unit back again I have taken out the gas valve and removed the solenoids. You have answered a question I had about the valve in that it is supposed to open another source for the extra gas. I think this is not happening so this is where I am with it. I will probably replace the gas valve. I don’t suppose there is a way to test the valve whilst it’s out of the unit?

February 21, 2019 at 11:06 am

Hi John – I’m not aware of a conclusive way to test the solenoids, but there are a few things you can check while you’ve got access. You should have two solenoids, probably opposite each other on the gas valve, each with it’s own electrical connection back to the PCB. You can check the wiring with a continuity tester to ensure there isn’t a broken wire between the PCB and the solenoids. If you can measure the coil resistance of the solenoids you can check they are not open or short circuit (Should be a few ohms resistance across the coil, as a guess). Also, if you apply power to the solenoid it should click as it actuates, though this is no guarantee it is actuating fully (note, it will only click when attached to the valve, if you separate the solenoid from the valve it probably won’t make any noise!) Hope this helps, Cheers, Dan

February 21, 2019 at 12:02 pm

Dan, I have applied 12 volt to both solenoids, one at a time. And literally blew down the gas inlet pipe of the valve. Both are operating ok and allowing air to pass as each one opens. The only other thing is I am now looking at the burner and in particular the flame rectification probe. It looks much worst than the one on your photo. It looks like it could snap any time now it’s corroded that much. So I suppose I’ll have to change it and see what happens. Again thanks for your help and if you don’t mind I’ll keep posting updates as it might help others.

February 21, 2019 at 12:14 pm

Hi John – looks like it’s good news about the solenoids! The probes should be available separately, or as part of a complete burner assembly. Yes, please keep posting updates – it’s great to have you on board! Cheers, Dan

February 19, 2019 at 12:09 pm

Hi , is the boiler meant to work with the 12v switch on control panel switched off. Mine does and I’m afraid that it might be taking power from the van battery. Help.

February 19, 2019 at 1:46 pm

Hi Terry – it depends on what van you have and how it is wired, in our Hymer B544 the boiler is wired from a permanent 12V feed so it will work with the 12V switched off on the control panel (this only turns off some lights, 12V sockets and the water pump). Yours may well be the same. The boiler itself will draw no power when switched off from it’s own control panel, only the frost protection valve will draw some current, but this is minimal. Hope this helps, Dan

February 19, 2019 at 4:09 pm

Thanks for replying Dan .

In that case , does it still get its power from the leisure batteries? I’m asking because 3 times now in the last 4 months when we have had a heavy nights usage in the van , dark nights and cold so heater on all night and 7 or 8 hours of tv, and only driving 2-3 miles a day . After the third day our leisure batteries are reading 12.6 v , but the engine battery is 11.4 v. Had to call the AA to get the van going and they put a tester on battery ( only8 months old) and all was good and same for alternator .

February 19, 2019 at 4:34 pm

Hi again Terry – In our van the heater is supplied from the Leisure battery (there are basically two sets of circuits fed from the leisure battery via the Elektroblock, one lot are switched from the panel and the others are permanently live – the heater is on a permanently live one). It may be that yours is powered from the starter battery for some reason – one way to check this would be to disconnect one of the battery terminals on the starter battery and see if the heater still works. I suspect it is something else that is draining your starter battery……

I keep a little cigar lighter to cigar lighter jump pack in the bus in case I have a flat starter battery – plug one end into a socket in the van and the other into the socket in the dash & I can charge the starter battery from the leisure battery, 20mins or so should be enough to start the engine. Ours is made by ‘Ring’ but it looks like it’s not available anymore, here’s a similar thing from Draper I found on Amazon:-

February 21, 2019 at 4:06 pm

Hi Dan , the cig to cig jump pack you linked to……does it work , have you tried it? I have a suaoki power pack that should do the job but tried it twice now and it has never worked even though it is always 100% .

February 21, 2019 at 6:02 pm

Hi Terry – I’ve not tried the Draper one but my Ring one works and has got me out of trouble on a few occasions (I couldn’t find the Ring one online anymore, but the Draper unit I linked is the same type of device) – they work differently to power packs. A power pack jump starter has to supply enough current to jump start an engine from it’s internal battery, so they don’t always manage to start large Diesel engines. The cigar lighter to cigar lighter device takes energy from your leisure batteries and puts in in the starter battery, so it is like putting a charger on the battery. You will need to leave it for a while to allow the starter battery to charge up (20mins is normally enough) – basically you put 10 Amps in for a few minutes to allow the starter to draw many hundred Amps for a few seconds. Cheers, Dan

February 21, 2019 at 7:34 pm

Thank you so much for all the info and advice . Will get the Draper one . Thanks again . Cheers.

February 24, 2019 at 8:41 pm

Hi Dan, really interesting write up. I believe I have the 3402 combi on my boat and it produces smoke through the internal vents on heater mode. I’ve noticed there is a small plastic tube which runs to a hole in the hull. I’ve noticed the tube is black inside as if stained by smoke. The system produces heat and hot water but obviously not safe to use as it is. Any ideas appreciated, thx Richard

February 24, 2019 at 9:18 pm

Hi Richard, the small plastic tube is probably a water overflow/vent line – interesting if this has had smoke in it?!?. More of a worry is smoke coming through your internal vents, as the hot air system should be completely isolated from the flue gases. My guess would be a damaged flue emitting smoke into the boiler area which is then being pulled in by the room fan, so would check the flue first. Let me know how you get on, Cheers, Dan

February 27, 2019 at 8:50 am

Thanks Dan. I am trying to arrange for someone to come and service the unit but this is proving tricky. I am tempted to remove the flue pipe at the boiler end as this will allow me to check the full flue length for blockages as well as check to see if it is fitted correctly. I know you’ve said it may be difficult to reconnect and should have new o-ring. Is it a push fitting with jubilee clip or is there any kind of sealant required?

Having had one of these systems in a caravan before the smell is similar to dust being burnt off the elements when the system has not been used for a while. I think first I will get some air duster and attempt to clean the heat exchanger fins from the top. I have also noticed dust on the room fan so I plan to dismantle this part of the housing and clean it.

February 27, 2019 at 1:20 pm

Hi Richard, The flue is just a push fitting with a jubilee type clip, no special sealant required – the recommendation to replace the o-ring comes from Truma themselves. It’s just a bit fiddly to get the flue pipe back on as it is a thin corrugated metal tube that is easily deformed, but if you are careful you should be OK. The blown hot air systems can smell a bit dusty, especially if they’ve not been used for a while – I believe this is fairly normal. Cleaning the heat exchanger and the room fan inlet filter should help. Cheers, Dan

March 1, 2019 at 6:51 pm

Hi dan, thx for this. Should there be an o-ring at both ends of the flue i.e. side connected to the boat and side connected to heater? I have found an o-ring lose in the heater cabinet! Looks like it most likely came from the side connected to the boat.

Thanks again for your help.

Rich

March 4, 2019 at 6:21 pm

Hi Rich – I’m not 100% sure as I’ve not seen a boat install, but I would expect there to be an o-ring on both ends of the flue….

Hope this helps, Cheers, Dan

March 9, 2019 at 3:13 pm

Update on my problem with 3402…

After lots of faffing I’ve pinned down that smoke is being produced from under the boiler unit. This is most noticeable when the heater is set to high but a burning smell also occurs after a while when just set on water heater.

I have checked around the system with a gas analyser and no Carbon monoxide was detected. I’m really confused as to where the smoke is coming from! The unit is very hard to access but I think it will neesd to come out for further checks which is a real pain!

March 10, 2019 at 6:14 pm

Hi Richard – sounds like an interesting problem, a pain that it’s got to come out but let us know what you find! Hope you get it sorted soon and if you have any further questions please don’t hesitate to ask! Cheers, Dan

September 1, 2019 at 7:34 pm

Hi

We have a truma 3402 heater/boiler in our motorhome . I have noticed the flu pipe is sooty and there are also sooty deposits in the condensation which drip from the flu cowl which stain the cowl and paintwork. What could it be? We have a CO detector in the motorhome and it has never gone off.

September 1, 2019 at 9:12 pm

Hi Peter, sooty deposits indicate incomplete combustion – so either too much gas or not enough air. It may be that there is a blockage in the combustion fan or air intake pipework that is preventing enough air reaching the burner. There may also be a build up of deposits on the burner itself that is affecting combustion. Incomplete combustion will also cause carbon monoxide to be present in the exhaust gas but as long as the flue pipework is intact it should all be vented outside so unlikely to be picked up by an internal CO detector.

We have also experienced sooty flue gas which we put down to a dodgy gas bottle (I think there was some oil or other contaminant in the gas), so if you’ve only noticed this after changing the gas bottle it may be worth trying a different bottle to rule it out. If it is the gas you will probably find also find sooty marks on the upper fridge vent when running the fridge on gas.

Hope this helps – let us know what you find! Cheers, Dan

September 21, 2019 at 5:30 pm

Hi Dan

Great article. Lots of good info. One thing tho’ – on the last photo of the article – the PCB board – there’s a component at the top of the board that projects beyond the board housing. Looks like a switch of some sort. Any ideas what this is? I’m thinking a reset switch or could it be a test point? Like to know as my C3402 is currently non-functioning and I haven’t found a solution yet. Thanks

September 24, 2019 at 11:51 am

Hi Cliff – that component is a jack socket (similar to the type used for headphones), Truma sell a remote room temperature sensor that plugs into it (connecting a temperature sensor here overrides the room temperature sensor built into the control panel). What are the symptoms or the issue you are having with your C3402? Cheers, Dan

September 29, 2019 at 9:51 am

Hi Dan

Thanks for that info. The issue I have with my unit (which is fitted into my boat in France) is that it doesn’t fire. I supply it with 12v dc and when switching on at the thermostat control an orange neon light comes on and a quiet fan running sound. Nothing else – no solenoid thumps or gas lighting type whoomp.

Confusingly, when leaving the thermostat controller in the ‘on’ mode and turning off the 12v supply and then waiting 30 secs or so before turning the 12v supply on again the red light comes on immediately and there is the sound of a fan running very hard for a few seconds before stopping. The length of time the fan runs is dependant on the amount of time it has been in the ‘no 12v state’. Turning off from this state at the controller returns the unit to the ‘orange light and quiet fan’ state.

For information – the unit worked to a degree last year, in that it would take repeated attempts at switching on and off at the controller to get the solenoid thump to occur and the Whump of the gas lighting. Most times the red light came on straightaway.

Upstream on the gas supply side there is a safety cut-out trip that feels like its working – but to be honest I haven’t been able to 100% establish this. Also I’m aware that the thermostat controller is a little suspect in that the quiet fan noise referred to above will cease if I ‘jiggle’ the temperature knob. I have been able to locate a replacement controller but am loathe to buy it if there is a bigger problem with the unit and I can’t get new parts.

Over to you Mr Starter!

September 29, 2019 at 7:26 pm

Hi Cliff – sounds interesting! The quiet fan running noise should be the combustion fan (you should be able to confirm this if you can get to the unit) and is normal during start-up, the orange light just means a heat demand from the hot water temperature sensor (assuming you have the same controller/thermostat as me). If it is in the ‘orange-light and quiet fan’ state for too long without lighting it should time out and go into fault (red light on) – is it doing this? If it is stuck in the startup phase and not going into fault I would guess a problem in the control electronics rather than the gas/ignition/burner bits. The behaviour you describe from last year point to this too, if the solenoid was working every time but the gas failing to light it points to a problem with either gas supply or ignition, but the fact the solenoid only worked occasionally sounds more like a control problem. Unfortunately the electronics are quite expensive – do you know anyone nearby with the same unit that might lend you a know good thermostat or control PCB to try? – they are both quick and easy to swap out & this should at least help conclusively narrow down where the problem is! Hope this helps, let us know how you get on! Cheers, Dan

October 8, 2019 at 4:14 pm

Hi Dan,

Thanks for all the advice. Much appreciated.

I can hear the piezo device sparking but cannot hear the fan starting up. Is that very loud if you are right next to the unit? Unfortunately, my heater unit is located in an external cupboard, so after switching on I have to jump outside and run around the van in order to hear the tell-tale noises…

After hearing the sparking a few times there is a click and the red light on the control panel comes on. All other gas systems (hob, cooker etc) are working fine

Any ideas?

October 8, 2019 at 4:59 pm

Hi Bill, the combustion fan is not very loud but you may be able to feel it running through it’s casing. It’s probably easiest if you can rope someone in to operate the controls from inside the van while you listen to the unit outside.

The click of the gas solenoid and the sound of the gas lighting should be obvious, (the gas solenoids are much louder then the rapid clicks from the ignitor). If the gas is lighting but the unit still goes into fault this suggests a problem with the flame sense system. If the gas solenoids click but there is no ignition then it is probably a faulty solenoid resulting in no gas to the burner. If there is no click from the solenoid then it is either a faulty/sticky solenoid or a problem with the electronics driving the solenoid.

Hope this helps! – let us know how you get on…………

Cheers, Dan

October 8, 2019 at 5:11 pm

Thanks Dan,

OK. Just tried that. I stuck my ear to it while the misses switched it on. I can definitely hear/feel a motor (fan?) running. There is a loud click (gas solenoid?) then the piezo fires several times very fast. The boiler doesn’t fire up, and the red light inside comes on.

I’m thinking no gas, but fridge. cooker, hob etc are all working fine.

October 8, 2019 at 5:21 pm

Hi Bill, it could be a blockage somewhere in the gas supply to the boiler. Do you have a gas isolator to the boiler? (my van has separate gas taps for the fridge, boiler and hob under the sink) You could isolate the gas here and then unscrew the gas supply pipe at the boiler, and then briefly turn the gas back on to see if you have gas to the boiler (obviously be careful there are no sources of ignition nearby!) There could also be a blockage in the gas jet inside the boiler, you could remove the solenoid unit from the boiler but leave it connected to the gas supply line and electrical wiring (I think there is enough play in the wiring to do this) – you can then try the startup sequence again and see if you get gas out of the end of the gas jet when the solenoid operates?

Cheers, Dan

October 8, 2019 at 5:41 pm

Thanks Dan,

Much appreciated. I ‘ll have to have a look and see if I have a gas isolator. I have never spotted one, but then again I have never looked.

Also, I’ll try and have a closer look at the gas entry to the boiler and see if there’s a blockage as you advise.

Your assistance so far is much appreciated. If I find a solution – or a further problem – I’ll let you know.

Many thanks,

Bill

October 8, 2019 at 6:02 pm

Good luck Bill!, we await updates 🙂

October 9, 2019 at 5:10 pm

OK.

(Not much) progress report.

I found the gas isolators. They seem to work.

There IS gas getting to the input side of the solenoid valve, but I can only pull the assembly a few millimetres away from the boiler so I am reluctant to fire it up in a disconnected position in case something nasty happens.

I can feel the solenoid valve clicking open so assuming that the gas is getting in OK. There is a chance that I’m wrong of course.

However assuming that the gas is present, I suppose the next logical step is to check that the piezo I can hear clicking is actually producing a spark in the right place. I have no idea how to check that!! Is it easy?

As always, many thanks for your assistance – and patience!!

Cheers,

Bill

October 9, 2019 at 5:30 pm

Dan

Just to give you an update. I’ve left the boat now with it all tucked up for the winter. I won’t be going back until late April/May, so the saga will carry on then. I’ll let you know what happens. FYI you said that the yellow indicator lamp on the control panel was to show a heat demand from the hot water sensor, however my Truma does hot air only – no water. Does this change anything? Assuming not I’ll be back in the Spring. All the best.

October 11, 2019 at 4:45 pm

Hi Cliff – assuming you have a C3402 it will have capability to do hot water – it may just be that it is not plumbed in to do it in your boat (the unit is fine running hot air only with no water in it). I don’t know what the behavior or the orange light would be in this case?!?

Anyway – enjoy the break we’ll catch up in the spring ? Cheers, Dan

October 11, 2019 at 4:40 pm

Hi Dan,

There are two separate cases here. Cliff has the boat. I have the motorhome.

Anyway, kind of good news from me. On looking through my paperwork I (surprisingly) discovered that my van, although second hand is still under warranty from the seller. I phoned them through the symptoms and they have told me to bring it in to be fixed! I hope that they will subsequently provide me with an explanation as to the fault, and if so I will share it on here.

Cheers,

Bill

October 11, 2019 at 4:49 pm

Hi Bill – apologies, got myself confused! Erroneous reply now deleted 🙂 Anyway – good news on the warranty!, hopefully they getting sorted for you quickly and it will be interesting to hear what their diagnosis is. Cheers, Dan

October 22, 2019 at 4:46 pm

Hi Dan,

It turned out to be the combustion fan! It has been replaced and all is well.

We are away at the weekend, so a chance to check that it continues to work!

That means that the fan/motor I could hear/feel running must have been something else!

Thanks for all your help.

October 23, 2019 at 11:09 am

Hi Bill – glad to hear it got sorted, and thanks for updating us with the outcome, happy travels! Cheers, Dan

November 10, 2019 at 6:20 pm

Really well explained Dan. Very much appreciated. We have one in our B694 Hymer and while it is going well it’s great to have this knowledge at our fingertips.

November 11, 2019 at 5:01 pm

Hi Steve – many thanks for the feedback, happy travels! Dan

November 24, 2019 at 3:42 pm

Hello, Some very helpful information here!

I have a 1998 Hymer Starline with a c3400 Truma. It lived a great life with me and always functioned correctly. I just sold van and in two days the new owner says the bolier is running with orange and green light and fans running but no heat. No heat from Flue and it is not tripping out on red light. Gas is food in van and there is good temperature. I find it strange as it always had a red light for me if a problem. Never ran with cold air only. Water doenst appear to be heating.

Any one have any ideas?

November 25, 2019 at 9:35 am

Hi Richard – sounds like a similar problem we had with our boiler – it’s as though the boiler thinks the gas is lit but it’s not! However with ours as soon as we switched the boiler off and then on again it failed to light and went into lockout with the red light, we couldn’t replicate the orange/green light but no heat issue again. Is the new owner experiencing this issue every time they try to use the boiler?, Can they hear the boiler igniting (or trying to ignite?) – I find the easiest way to pinpoint the problem is to listen to the startup sequence and try to work out where the process is falling over. If you search through the comments on this page you will also find the details for Bob Gardner, I don’t know him personally but he got in touch to say he checks/repairs Truma PCBs, he may be able to help. Hope this helps, let us know how you get on – Cheers, Dan

November 26, 2019 at 12:57 pm

I’m the new owner Richard referred to and a Motorhome rookie. I tried a few things but here’s what eventually got the system to work.

Turned everything off – boiler, main house power switch and gas feed to boiler.

Turned on the boiler at the control panel and it lit up green and amber.

After a couple of minutes it lit up solid red as expected. I turned it off again.

I then turned the gas feed on, followed in succession by the boiler switch and main power to the house.

I could then hear some startup clicks and the gas lighting.

Everything is heating fine again now but I’ve no idea what caused it to originally appear to be working normally but not actually igniting.

Kieran

November 26, 2019 at 4:54 pm

Hi Kieran – glad everything is working properly again for you now! – sounds like it may have been a temporary electronic glitch, perhaps from the heating not being used for a while (hot water only over the summer months)?. Anyway, hope it doesn’t cause you any further problems, happy travels! Cheers, Dan

November 26, 2019 at 5:04 pm

Thanks Dan & Richard.

November 28, 2019 at 12:47 pm

Hi Keiran/Richard – Bob Gardner has been in touch to highlight the risk of unignited gas in the case of a boiler not igniting but not going into lockout. If the gas solenoid remains open unburned gas will be expelled from the flue, and potentially build up inside the boiler/boiler cupboard creating an explosive atmosphere. When I had a problem with the boiler not lighting but not going into lockout there was no gas flowing, but your issue may be different. Please be aware of this if you experience any issues in the future. Cheers, Dan

November 27, 2019 at 9:27 pm

Hi Dan, I really hope you can help.

Our Trumatic C3400 boiler is being very temperamental and only working intermittently. There’s no rhyme nor reason we can find for it just deciding not to work!!?

We go through all the usual start up procedure:

1. combustion fan running

2. gas solenoid clunk

3. ignitor clicking away

4. the muffled whump of the gas igniting…

then the red light comes on. Sometimes it starts first time, other times I’ll turn it on 2 or 3 more times before it stays on, or I can still be flicking it on and off 30 minutes later (100s of clicks!!) before it’ll stay on! We’ll go to bed with it working but wake up in the morning and the red light will be on again. We’ve had someone look at it and service the boiler and he changed the ignition system /probes but it’s still playing up.

We’re hoping to go skiing in it in January so any advice would be very much appreciated.

November 28, 2019 at 12:59 pm

Hi Kimberley, if the gas sounds like it is igniting reliably each time but the boiler still goes into lockout it may be as issue with the flame sense rather than the ignitor – was the flame sense electrode replaced at the same time as the ignitor electrodes? If so it may be as issue with the flame sense electronics on the PCB. If the gas is not lighting reliably (you may hear a series of ‘whumps’ as the gas lights but goes out again) then it could be an issue with the ignition or gas flow. If the ignitor unit was replaced at the same time as the ignition electrodes it could be a failing solenoid or a restriction in the gap pipework/gas jets. Do you know anyone nearby with a working C3400? – swapping the PCB from a known good unit only takes a few minutes and this would allow you to quickly confirm if the PCB is at fault (Bob Gardner may also be able to check your PCB for you – see this thread for his contact details). Hope this helps, let us know how you get on and I hope the skiing goes well! (you may find some useful info here – https://motor-roam.co.uk/motorhome-ski-resources) Cheers, Dan

December 1, 2019 at 8:14 pm

Dan, thanks so much for your help.

It seems to have completely given up today, we’re getting nothing at all?And the fridge has decided to stop working on the gas too now!! It never rains but pours eh?

We’re currently in between houses so living in it full time, mainly wild camping, but we’re going to check into a campsite til we get things sorted.

Again, many thanks and I’ll keep you posted?

December 2, 2019 at 8:58 am

Hi Kimberley, sorry to hear you are having more problems! If the fridge is also giving problems it might be worth checking the gas regulator/gas bottle – I’ve heard reports of gas bottles occasionally having some oil in them which can clog up regulators, the gas flow may be reduced but not enough to notice on the hob. If you can do a temporary swap to another bottle/reg you should be able to rule this out. I’ve also got some articles on here about issues we’ve faced with our fridge on gas which may help, just put ‘fridge’ into the search box on here. Good luck! Enjoy the adventure and keep us posted 🙂 Dan

January 1, 2020 at 8:55 am

Hello DAN,

My trumatic C 3400 have problem. In boiler position it works.

when I turn on heating and on 20 degree it start burning, ventilator works , but burning stops, and start again. Stop/Start. No red light.

If I turn to 5 degree it working, after some time I turning to 10 if works. And slowlly I can turn to 20-25 degrees. I notice that fan works in one speed. On 5 or 20.

Thanks.

January 1, 2020 at 1:57 pm

Hi Tadas – That’s an interesting issue, and not one I’ve seen before! It may be a problem with the control electronics, or potentially an issue with one of the two gas supply solenoids (I.e. boiler only working on one solenoid and having issues when a high heat demands calls for the second solenoid). It may be worth giving Bob Gardner a bell on 07887705480, he tests/repairs Truma electronics in his spare time. Hope this helps, Cheers, Dan

January 3, 2020 at 7:06 pm

Hi Dan

Read your blog today as we are having issues with our heating. We have a C6002 which is in a Bessacarr E795. All was well until today we have no heating but hot water. The boiler doesn’t kick in for heat in any mode unless we disconnect one of the connectors from the small bulb like sensor. No fault codes showing and when we try to turn the heater from 1-9 it no longer clicks. We are away in Cromer and have had to purchase a small heater to keep us warm. Any ideas what could have happened?

Our digital control EC200 is showing a random temperature of 26.7c not sure if this has anything to do with it?

Kind regards

Darren

January 3, 2020 at 7:42 pm

Hi Darren – assuming your EC200 reads the room temperature from the same sensor as the boiler, and the boiler only operates with the room temperature sensor disconnected my guess would be that the room temp sensor has failed. It sounds as though with it connected the boiler thinks the van is warm enough whatever the dial is set to, and with it disconnected the boiler then assumes the van is cold and provides heat. The hot water would work fine in this case as the room temp sensor has no bearing on the water heating. There should be no harm in running the boiler with the room temp sensor disconnected, but bear in mind it may just keep heating the van no matter how hot it gets in there until you turn it off!. In some of the older units (like my C3402) there is a room temp sensor in the boiler control panel, and the system will revert to using this one if the external sensor is disconnected.

Hope this helps, let us know how you get on! Cheers, Dan

March 25, 2020 at 11:56 am

Hello Dan

your article is most helpful. I have the Truma c3402 in a 1998 Hymer. It is leaking water underneath the van when I turn the taps to hot. On cold it seems ok. I thought the dump valve may be stuck open. contacted Truma who told me that the frost safety valve was also the dump valve. a blue knob to the left of the heater housing. It does not seem to lift but turns to open and close. I have tried it in both positions, same result, still leaking quite badly. looking underneath I do not see a plastic leak pipe, the water is simply coming out through the floor. Can you help with this please

March 25, 2020 at 2:27 pm

Hi Charles – thanks for the comment!

It does sound like a leaking dump valve – though with an open dump valve you will usually get water leaking out of the bottom of the van whenever the water pump is running regardless of whether the taps are on hot or cold. The easiest was to check is to follow the hot water output hose from the top of the boiler – it should go to the dump valve on the floor of the van near the boiler.

Is the water coming out through the floor directly underneath the boiler? – it may be that there is a split/leaky hose somewhere on the hot water side, was the system fully drained down for winter? (i.e. is it possible that there is some frost damage?)

Hope this helps, let us know what you find!

March 27, 2020 at 1:06 pm

Hello Dan

solved. I assumed that the blue control turned the valve on and off. what I could not see until I moved some heating ducts, that there is a blue push button on the side of the unit. that was in the open postition. The plastic drain pipe was not going through the outer floor hole. thank you kindly Sir

March 27, 2020 at 1:11 pm

Hi Charles – thanks for letting us know, glad you got it sorted! Cheers, Dan

June 25, 2021 at 1:41 pm

Hi Dan

the boiler would not ignite a few weeks ago.. I stripped it and found that the flame rectification sensor was very dirty with a carbon build up. I ordered a new one , it came in a kit along with the two igniter electrodes. , described as being suitable for 3402and 60800 heaters. It was clear that the electrodes were not the same. All three were shorter than the originals and the securing hole was on the opposite side. I sent them back for a refund. I have tried to get the correct sensor , no luck. I decided then to clean the original, put it all back together and it works fine. just a heads up for anyone in a similar situation. any idea where I might get the correct one. I have tried AM Leisure., and a few other companies both in UK and Europe.

June 27, 2021 at 6:12 pm

Hi Charles – good work getting the system working again without new parts 🙂 I’ve found LeisureShopDirect to be pretty good for Truma parts. Truma themselves are also generally quite helpful if you contact them directly (they may not be able to supply parts directly, but should be able to confirm the part number for any parts you need to avoid getting sent the wrong bits from suppliers) Hope this helps, Cheers, Dan

November 1, 2021 at 5:17 pm

Hello again Dan

still having a few problems with the boiler.. It will ignite eventually after many attempts. strange thing is that if I switch it off after running for a few minutes, it will start up again straight away. I have managed to track down the two igniter electrodes but cannot find the flame rectification electrode anywhere. the part number is 34000 76500. I have tried leisure shop. and quite a few others in UK, same answer, obsolete parts. I bought the ignition electrodes from a company in the Algarve.

November 1, 2021 at 7:06 pm

Hi Charles – sorry to hear you are having problems sourcing parts. Have you tried contacting Truma directly to see if they can help?. Another option may be to buy a whole replacement burner assembly, when I replaced mine it came with all the electrodes attached. Hope this helps, Cheers, Dan

March 26, 2020 at 5:27 pm

Can I ask where did you purchase the burner assembly unit from, I can’t find one at the moment?

March 27, 2020 at 12:58 pm

Hi Patrick – my burner assembly came from leisureshopdirect.com, but looking on their website I can’t find a part available to buy right now. It might be worth giving them a call to see if they have anything stashed away. Failing that Truma themselves are usually fairly helpful, they may be able to point you to a stockist if they can’t supply a part directly. Hope this helps, Cheers, Dan

March 31, 2020 at 3:04 pm

Hi Dan,

Thanks for your reply i have been intouch with leisureshopdirect.com, Just awaiting for a reply they are getting intouch with truma to locate one. Can i thankyou for the post on how to strip and assemble the heater, This has been such a great help, I have had one accident with the air flow sensor i left it hanging down and when i moved the heater i have flattend the fuse. Any advice on how to test the fuse pcb would be appreciated. Patrick

March 31, 2020 at 5:28 pm

Hi Patrick – glad to be of assistance! From memory the air-flow sensor is a type of ‘hot-wire’ sensor – if you can bend the sensing element back up to where it was without the leads breaking it should be OK. There should be some measurable electrical resistance across the sensor (if possible disconnect it from the heater while measuring it, otherwise you might be measuring the heater circuitry rather than the sensor!), if it is open-circuit then it is likely to have been damaged. Hope this helps, cheers, Dan

April 1, 2020 at 3:27 pm

Hi Dan,

I have made my mind up whilst i have the heater out i am going to change the air flow pcb and the thermostate it will save doing it in if anything happens in the future. May do the solenoid aswell. Any tips on what tool to use to release the pins from their housing.

Patrick

April 1, 2020 at 6:52 pm