80 Series Land Cruisers come with an electrically actuated centre diff lock, and depending on specification locking front and rear axle diffs too (my Japanese import HDJ81 had all three diff locks fitted).

On my truck the centre diff lock stopped working (which also stops the front/rear diff locks form engaging, as the system checks that the centre lock has engaged before actuating either of the axle locks). Here is some info on the system and how to go about troubleshooting it:-

The centre diff lock actuator is a motorised unit that sits on top of the transfer case and actuates a small gear via a worm and wheel gearbox driven by a permanent magnet motor. There is a clock spring arrangement to allow the motor to preload the gear until the lock can actually engage (sometimes you need to rotate the centre diff by driving the truck before the lock can physically engage) and limit switches so the gear only rotates a certain amount in either direction. The gear physically moves the diff lock mechanism within the transfer case. There is also a plunger switch fitted to the transfer case that engages when the diff is actually locked.

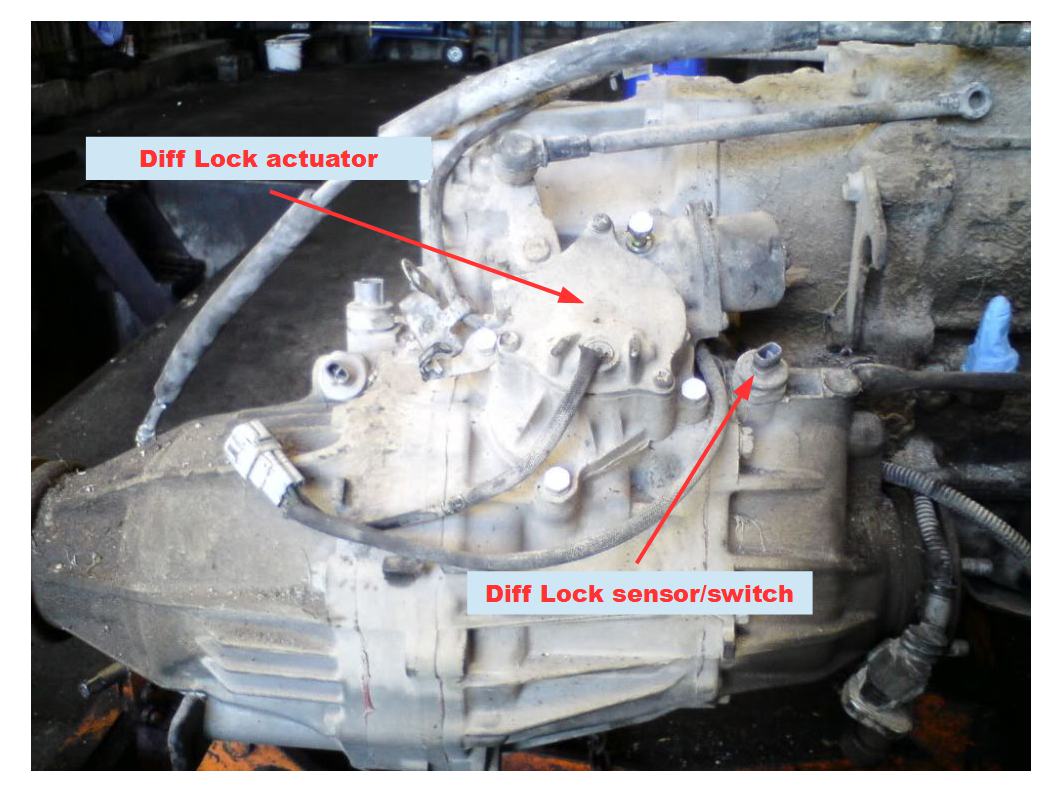

Here is an pic of the transfer case showing the actuator and the switch:-

There is just enough room to get to the actuator and switch by crawling under the truck and reaching up above the transfer case, but you have to work by feel as it is very difficult to see what you are doing!

The diff lock will normally operate automatically when selecting low range, or can be engaged from the ‘centre diff lock’ button on the dash if you have one. When the lock is engaged the yellow centre diff lock light in the instrument cluster will light up.

In this picture you can see the centre diff lock light and the button, together with the red lights for front and rear axle diff locks (picture is from a left hand drive truck):-

Failure Mode 1 – Faulty diff lock sensor/switch

If you can hear the actuator motor operate when you select low range, or press the button the the dash, but the yellow light on the dash does not come on, it is possible the sensor/switch has failed (make sure the bulb hasn’t gone in the dash first! – it should come on briefly during the ‘bulb check’ when you first turn the ignition on)

With the wiring disconnected from the switch you can unscrew the switch from the top of the transfer box. Using a multimeter or test lamp check for continuity between the two electrical contacts on the top of the switch, you should get continuity (a short circuit between the two contacts) when the switch plunger is pressed in. If there is no continuity you can sometimes get it working again by spraying contact cleaner, brake cleaner or similar into the plunger mechanism and actuating it a few times. If you can’t revive the switch it is at least easy to replace it for a new one!

Failure Mode 2 – Faulty actuator motor

If there is no action from the actuator at all one thing that can cause it is the magnets falling off the inside of the motor housing and jamming it up. Once you remove the actuator from the transfer box it is fairly easy to strip it down to check it out. There are four bolts holding the unit to the transfer box (you can see these in the picture at the top of this page) – it is a bit fiddly to get to these while the transfer box is still in the car but it just about possible to undo them, unplug the electrics and wiggle the whole unit out from above the transfer box. The unit is sealed onto the transfer box with instant gasket type material so it might need a bit of persuasion to come loose.

You can see the gasket (red material) in this picture:-

The motor is the lump sticking out of the right hand side of the unit in the picture above, unbolting the fasteners allows you to withdraw the housing. If you have a loose magnet in the housing it is easy to fix it back in place using two-part epoxy (it should be obvious where it has come from)

Failure mode 3 – Seized shaft

You may find that the motor is actuating but the gear is not rotating, this can happen if the unit isn’t used for a while. If the shaft has become seized the clock spring will allow the motor to move to both to both engaged and disengaged position without the actual gear moving. Stripping the unit down and cleaning/greasing the working can usually sort this out.

My unit had all of the faults above but following the steps above got everything working normally again for just the cost of a few consumables (grease etc.) Second-hand units are very expensive and may have the same problems as your own unit!

Once you have everything working again it is worth engaging all the diff locks every few months even if you don’t need them – this will help to stop them seizing up from lack of use. Make sure you only actuate them on a low friction surface (grass, mud etc,) to reduce the stress on the axles/locks.

Hopefully this info has been useful – any questions of comments let me know below.

Found this information useful? – Want to support Motor-Roam?

Click here to find out how!

December 20, 2018 at 6:32 pm

Great information & Extremely helpful thank you.

February 17, 2019 at 11:38 pm

Hi,

What should I disconnect to use only low gear without central diff lock???

Regards from Poland 🙂

February 18, 2019 at 10:13 am

Hi Mike – If you disconnect the wiring at the diff lock actuator motor you should be able to select low range without the centre diff lock automatically engaging. Hope this helps, Cheers, Dan

May 11, 2019 at 8:13 am

G’day Dan,

I have the problem that the actuator cable is to short to reach the switch. I don’t understand why. it’s short about 50mm.

I rerouted as much wire as I can to get as close as possible to the switch but I’m out of wire and 50mm short…drives me absolute nuts!

Any Idea?

May 12, 2019 at 9:46 am

Hi Chris – No idea what it would be 50mm short! I would be fairly easy to extend the wires if you need to though:- Disconnect the battery, then cut the wires some distance back from the connector. You can then add in extra wire (a linesman splice is best, there’s lots of tutorial videos on youtube) covered with heatshink (glue lined heatshrink preferably). This should allow you to route the cable however you like, hope this helps! Cheers, Dan

May 12, 2019 at 1:11 pm

I had had a 2nd, 3rd and 4th look at it and I think all the wires and connectors got mixed up when reinstalling the gearbox after a clutch repair. I have 3 plugs they look identical. 2 of 3 won’t reach the switch and I found the 3rd one connected to the connector facing upwards right below the word actuator on your first picture. I took that cable and connected it to the switch. Still no dash light. I also don’t know if it is the correct cable in the switch. Is there a way I could find the right cable with a multimeter?

May 13, 2019 at 3:53 pm

Hi Chris – Is the diff lock working just no light on the dash, or is the whole actuator playing up? With the car on and low range selected you could try shorting out the wires in the connector – this should cause the light on the dash to come on.

One way to prove you have the right connector would be to do a continuity check with a multimeter from the light on the dash to the switch connector (but I would check a wiring diagram first, just in case the wires go off somewhere else!) Cheers, Dan

May 25, 2020 at 9:30 pm

Thank you !!!!!

November 12, 2020 at 5:28 pm

Hi Chris – On my 1997 80 series fulltime4 wheel drive,i am having major problems

of disengaging after putting it on L. I put it on L and the diff light came on and drove for a short distance and then put it on H but the diff light still on also i turned the car right to park on my driveway but noticed that it was struggling to move as if the brakes were on but if turn the wheels straight then it was okay to move forward or backwards.I have tried few times to put in H and L but no luck please help.

Kind Regards

Ash

November 12, 2020 at 9:55 pm

Hi Ash – it certainly sounds as though the centre diff lock is stuck on. First thing I would try is to check the actuator as described in this post. It may be that the diff lock has become stiff and the actuator doesn’t have enough torque to move it back to the ‘off’ position. Cheers, Dan

February 7, 2022 at 12:47 am

Hi Dan – If you remember in 2020 I asked for help for actuator motor freezing and couldn’t drive my car tried doing what you said by trying to remove the actuator motor from centre transfer case but due to my arthritis totaly failed . So i started the car every fewdays to keep the battery is charged and also put it in high and low gear and drove forward N backwards on my drive not turning. Hoping that the shaft will come loose but no luck until today I noticed when I started the car and the different light on the dash was off so I drove the car out of the driveway and yes it was okay i could turn the car normally so thank you very much Dan for your help .Now I have a problem with my speed sensor wire was very brittle which has snapped off near the plastic plug there is no wire on the plug for me to connect all three wires back onto it I’ve tried stripping the plug socket so I can get the pins out of the plug and soilder the wires on back on .managed to pull the white clip out but the metal pin will not come out any idea how i can pull out the three pins out

kind regards Ash

February 7, 2022 at 9:24 pm

Hi Ash – good to hear you are making progress with the transfer case!

The pins in electrical connectors are retained in different ways, but can usually be released by inserting a sharp tool down the side of the pin to release a small tang that locks them into the connector. On some connectors this has to be done from the front, on others from the back. Can you post a picture of the offending connector? – it might be one I recognise :). Cheers, Dan

January 1, 2022 at 4:41 am

Hi, I’ve put a new box in and needed to change my CDL unit onto the new box it is now stuck in lock with the light on, do you have to have the teeth on the units lined up or do they just keep turning the right way till it’s in/out?

Cheers

January 1, 2022 at 7:02 am

Hi Tom – the gear on the actuator turns a certain amount in each direction, so it is important that the tranfer case is in the same ‘state’ as the actuator when it’s fitted (i.e. if the diff lock is engaged, the actuator also needs to be in the ‘engaged’ position when fitting)

Hope this helps, Cheers, Dan

March 1, 2022 at 11:26 am

Hey guys I recently brought a 94 GXL have a broken wire that runs front drivers side front axle across to passenger side and runs to the rear, currently I only have RWD not full time 4 wheel drive as I’m suppose to would this wire be a differential lock maybe?

March 2, 2022 at 6:50 am

Hi Joseph – this wire may well be to do with the diff-locks but you should have ‘full time 4wd’ even without the diff locks working. If the broken wire is for the diff lock I would expect to see the diff lock light flash constantly when you try to engage that lock? Cheers, Dan

September 25, 2022 at 10:56 pm

A little trick that may get you out of trouble in the bush if your CDL actuator fails.

Remove the plug on the sensor switch on transfer case. Short it with a paper clip and tape it up or you could even extend the wires into the cab with a switch. Your CDL dash light is now on. (This is also a good test for the globe in the dash) This will fool the system into thinking the CDL is engaged and will allow the front and rear lockers to engage if you have them. This is not as good as fully locked but will be better than a 1WD and may help you get home.

Also when testing for failure points the relay in the left front foot well can fail.

September 27, 2022 at 7:10 pm

Hi Chris – good info, many thanks for sharing! 🙂 Cheers, Dan

September 6, 2023 at 8:08 am

Can you help my 80 series is locked in 4wd all the time all wheel drive

September 10, 2023 at 10:11 am

Hi Matthew – which diff is locked according to your warning lights? (I’m guessing centre diff?) Have you followed this guide to remove the actuator to determine whether the actuator has failed or if the difflock itself is stuck? Cheers, Dan

December 12, 2023 at 9:13 am

Hello, i have the Problem that the Center diff light does Not light up (Bulb Check) when i turn the car on, so my Front and Rear lockers are Not working. but when i Short the Switch the light does come on and my Front and rear lockers are working, but my Center diff ist Not locking in! I hear the Relain clicking in the car! I think the Problem is Conectet to the light Not Turning on when i start the car.

December 14, 2023 at 6:52 am

Sounds like your center diff lock motor/actuator is not engaging properly. The system is very analogue. You press the button on the dash, the relay in the footwell sends power to the motor/actuator. When the actuator moves into the locked position it closes the switch and the light on the dash comes on. The system now knows the Center is locked and it will allow the front and rear diff locks to be engaged.

The actuators are prone to failure. Deep water crossings are usually the cause. When you get it working you can extend the breather tube up the fire wall into the engine bay with your extended diff breather lines.

September 22, 2024 at 6:43 am

Hi , i have a 1990 and just fitted triple lockers and they arent working neither is my centre diff lock. No lights in dash and cannot hear actuator engaging and relay not clicking either so could it be just a relay? 🤞

September 22, 2024 at 10:19 am

Hi Kyle – when you say you have just fitted the lockers do you mean the vehicle was factory built without them? – if so I don’t know what it will have been equipped with in terms of wiring, relays, fuses etc. to support the lockers? I would recommend you get hold of a wiring diagram for your vehicle and verify all the wiring/controls associated with the system – hopefully it’s something simple! Let us know how you get on, it will be interesting to know what you find…..Cheers, Dan

December 12, 2023 at 9:15 am

*Series 80 24V 5 Speed Manual

June 16, 2024 at 12:49 pm

I have no power to the cables cuming to the actuator what can i check

November 8, 2024 at 6:08 pm

Great explanation, thank you!!!

A few questions-

* What is the part number for the replacement?

* Is it true that the 100 series will work for the 80 series as long as you align the correct colored wires?

* My internal motor with the copper strands turned black and my mechanic says I need to replace that part. Will other lesser expensive replacement’s parts have the same size motor components? Or do I have to replace the entire part?

* Please confirm this mechanism will engage the front axle.

* Please confirm it can be done without dropping the transfer case.

I am in Costa Rica so harder to find parts and good support!

Thank you in advance.

Chris 1991 LC VX

November 9, 2024 at 3:05 pm

Hi Chris – thanks for the comment, I’m afraid I don’t know the answers to most of your questions but perhaps someone else reading this may be able to help! I can confirm everything mentioned in this article can be dome without dropping the transfer case, though access would be much easier with the transfer case lowered. On the 80 series both axles are permanently engaged, the diff lock actuator simply locks the front and rear output shafts together so they rotate at the same speed and torque is split evenly between the axles. The the differential open the axles can rotate at different speeds and if you lose traction on both wheels of a given axle all the power will be sent to those spinning wheels. Hope this helps!, cheers, Dan